『Click here to download the product PDF: Explosion Proof Anti-Corrosion All Plastic Fluorescent Light BYS』

Technical Parameter

| Model and specification | Explosion proof sign | Light Source | Lamp type | Power (W) | Luminous flux (Lm) | Color temperature (K) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| BPY-□ | Ex db eb IIC T6 Gb Ex tb IIIC T80°C Db | LED | I | 1x9 1x18 | 582 1156 | 3000~5700 | 2.5 |

| II | 2x9 2x18 | 1165 2312 | 6 |

| Rated voltage/frequency | Inlet thread | Cable outer diameter | Emergency charging time | Emergency starting time | Emergency lighting time | Degree of protection | Anti corrosion grade |

|---|---|---|---|---|---|---|---|

| 220V/50Hz | G3/4 | Φ10~Φ14mm | 24h | ≤0.3s | ≥90min | IP66 | WF2 |

Product Features

1. The shell is made of high-strength molding. The transparent cover adopts polycarbonate injection molding with good light transmittance and strong impact resistance;

2. Labyrinth structure is adopted for the shell, which is characterized by good dust-proof, waterproof and strong corrosion resistance;

3. The built-in ballast is a special explosion-proof ballast with a power factor ≥ 0.95. The built-in disconnecting switch automatically cuts off the power supply when the product is opened to improve the safety performance of the product; It also has short circuit and open circuit protection functions. It is equipped with prevention circuits for the aging effect and air leakage of the lamp tubes, so that the lamps can work normally, with high efficiency and energy saving. It has wide voltage input range, constant power output and other characteristics;

4. Equipped with well-known brand fluorescent tubes, with long service life and high luminous efficiency;

5. Emergency devices can be configured according to user requirements. When the external power is cut off, the lamps will automatically switch to the emergency lighting state;

6. Steel pipe or cable wiring is acceptable.

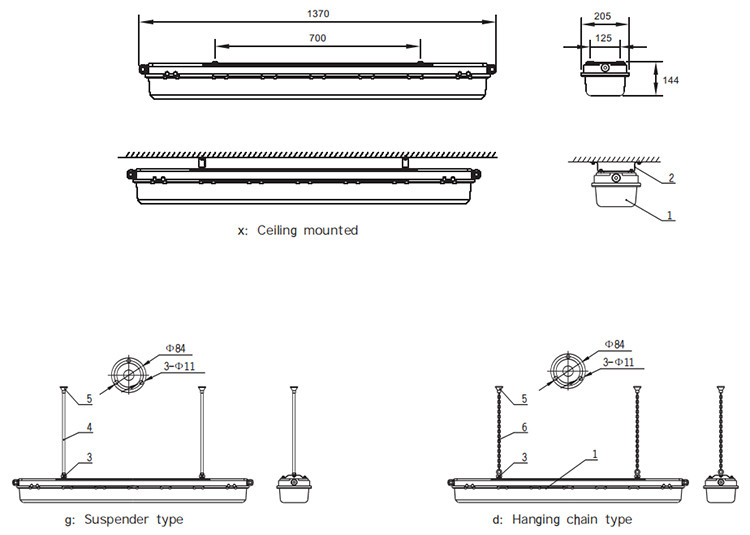

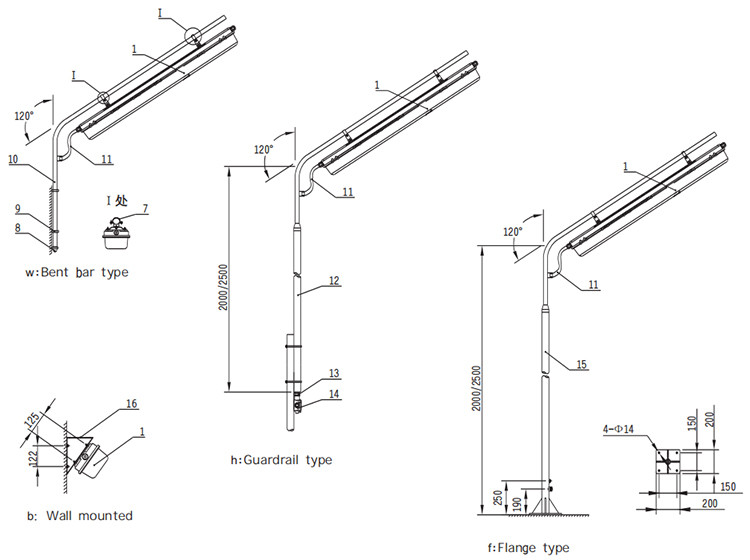

Installation Dimensions

Applicable Scope

1. It is applicable to the places in Zone 1 and Zone 2 of explosive gas environment;

2. It is applicable to the places in Zone 21 and 22 of combustible dust environment;

3. Suitable for IIA, IIB and IIC explosive gas environment;

4. Applicable to T1~T6 temperature groups;

5. It is applicable to work and scene lighting in dangerous environments such as petroleum exploitation, oil refining, chemical industry and gas station;

6. It is applicable to places with high protection requirements, humidity and corrosive gases.

Shenhai Explosion-Proof

Shenhai Explosion-Proof