Technical Parameter

| Explosion proof sign | Degree of protection | Rated frequency (S) | Cable outer diameter | Inlet thread |

|---|---|---|---|---|

| Ex db IIC T4 Gb Ex tb IIIC T135℃ Db | IP54 | 50 | Φ10~Φ14 | G3/4 or pressure plate |

| Model and specification | Impeller diameter (mm) | Rated voltage (V) | Rated speed (r/min) | Impeller angle | Air volume (m3/h) | Total pressure (Pa) | Installed power (kw) |

|---|---|---|---|---|---|---|---|

| BDW-1-2# | 200 | 380/220 | 2800 | 43° | 1230 | 112 | 0.09 |

| 1450 | 43° | 618 | 64 | 0.06 | |||

| BDW-1-2.8# | 280 | 2800 | 35° | 2921 | 190 | 0.25 | |

| 1450 | 1510 | 105 | 0.18 | ||||

| BDW-1-3.15# | 315 | 2800 | 3074 | 218 | 0.37 | ||

| 1450 | 1998 | 141 | 0.25 | ||||

| BDW-1-3.55# | 355 | 2800 | 3367 | 246 | 0.37 | ||

| 1450 | 2188 | 160 | 0.25 | ||||

| BDW-1-4.# | 400 | 3560 | 260 | 0.37 | |||

| BDW-1-4.5 # | 450 | 38° | 3450 | 142 | 0.37 | ||

| 42° | 4644 | 150 | 0.55 | ||||

| BDW-1-5 # | 5500 | 380 | 38° | 7655 | 116 | 0.55 | |

| 43° | 8316 | 123 | 0.75 | ||||

| BDW-1-5.6 # | 560 | 9581 | 173 | 0.75 | |||

| 48° | 11682 | 186 | 1.1 | ||||

| BDW-1-6.3 # | 630 | 41° | 10739 | 154 | 1.1 | ||

| 45.2° | 14454 | 169 | 1.5 | ||||

| BDW-1-7.1 # | 710 | 40° | 13400 | 178 | 1.1 | ||

| 960 | 43.5° | 16160 | 189 | 1.5 | |||

| 46° | 14498 | 123 | 1.1 | ||||

| BDW-1-8 # | 800 | 44° | 31325 | 180 | 2.2 | ||

| 37073 | 248 | 4.0 | |||||

| BDW-1-9 # | 900 | 46° | 35227 | 200 | 3.0 | ||

| 39800 | 230 | 4.0 | |||||

| BDW-1-10 # | 1000 | 48300 | 247 | 5.5 | |||

| 54300 | 268 | 7.5 | |||||

| BDW-1-11.2 # | 1120 | 42° | 56460 | 353 | 7.5 | ||

| 46° | 67892 | 415 | 11 |

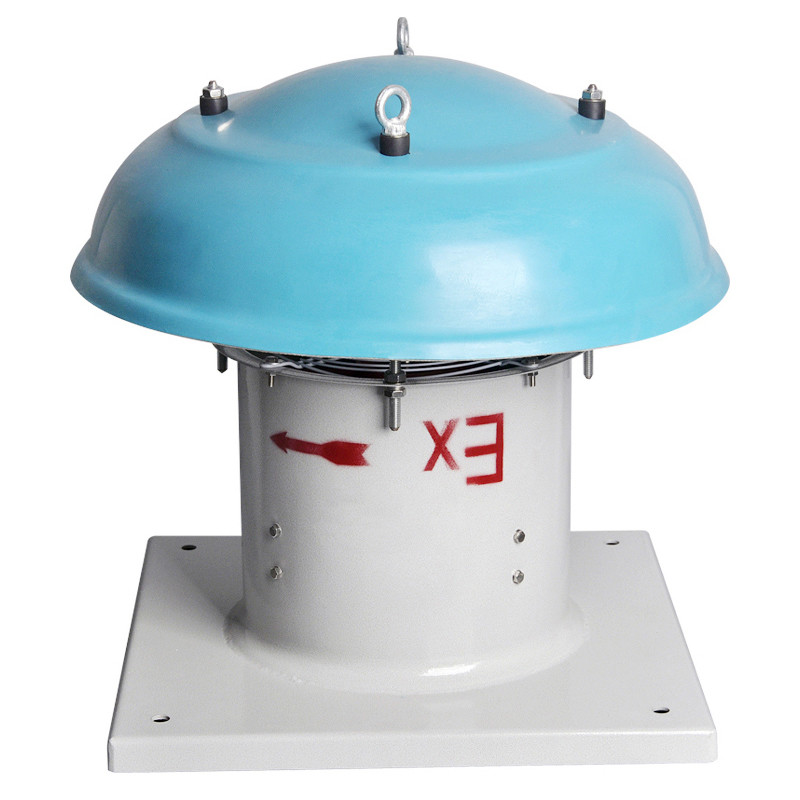

Product Features

1. The design of this series of fans adopts the three-dimensional flow theory of impeller machinery, and the experimental data is carefully designed to ensure the excellent aerodynamic performance of the fans, with low noise, high efficiency

Features such as low vibration and low energy consumption;

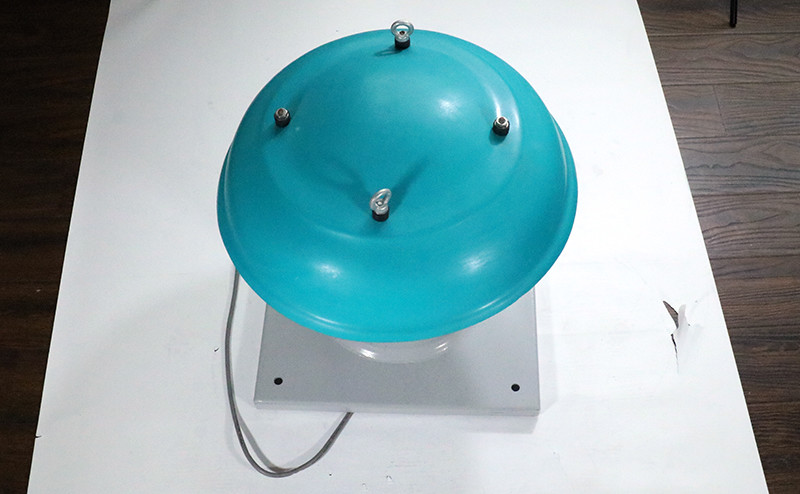

2. This product consists of explosion-proof motors, impellers, air ducts, hoods, and other components;

3. Transmission form: direct motor connection;

4. Maintenance method: Disassemble the hood for maintenance.

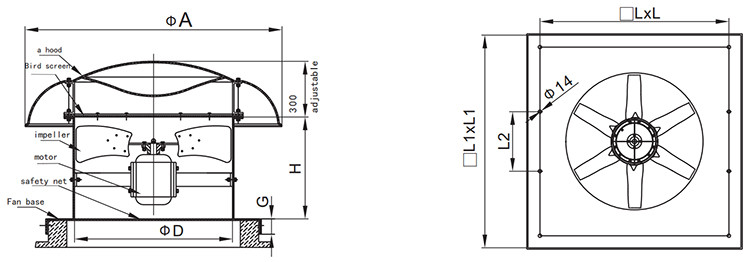

| Serial Number | Specification and model | φA | φD | G | H | □L×L | □L1×L1 |

|---|---|---|---|---|---|---|---|

| 1 | BWEXD-2.8# | 580 | 290 | 30 | 280 | 380×380 | 500×500 |

| 2 | BWEXD-3.15# | 580 | 325 | 280 | 415×415 | 535×535 | |

| 3 | BWEXD-3.55# | 580 | 365 | 320 | 455×455 | 575×575 | |

| 4 | BWEXD-4# | 650 | 410 | 370 | 500×500 | 620×620 | |

| 5 | BWEXD-4.5# | 650 | 460 | 370 | 550×550 | 670×670 | |

| 6 | BWEXD-5# | 900 | 510 | 50 | 370 | 600×600 | 720×720 |

| 7 | BWEXD-5.6# | 900 | 570 | 450 | 660×660 | 780×780 | |

| 8 | BWEXD-6.3# | 1000 | 640 | 450 | 730×730 | 850×850 | |

| 9 | BWEXD-7.1# | 1000 | 720 | 450 | 810×810 | 930×930 | |

| 10 | BWEXD-8# | 1250 | 810 | 630 | 900×900 | 1020×1020 | |

| 11 | BWEXD-9# | 1340 | 910 | 630 | 1000×1000 | 1120×1120 | |

| 12 | BWEXD-10# | 1650 | 1010 | 630 | 1100×1100 | 1220×1220 | |

| 13 | BWEXD-11.2# | 1800 | 1130 | 630 | 1220×1220 | 1340×1340 |

Applicable Scope

1. It is applicable to the places in Zone 1 and Zone 2 of explosive gas environment;

2. It is applicable to the places in Zone 21 and 22 of combustible dust environment;

3. Suitable for IIA, IIB and IIC explosive gas environment;

4. Applicable to T1-T4 temperature group;

5. It is widely used in oil refining, chemical, textile, gas station and other dangerous environments, offshore oil platforms, oil tankers and other places;

6. Indoor and outdoor.

Shenhai Explosion-Proof

Shenhai Explosion-Proof