Technical Parameter

| Explosion proof sign | Degree of protection | Rated frequency (S) | Cable outer diameter | Inlet thread |

|---|---|---|---|---|

| Ex db IIC T4 Gb Ex tb IIIC T135℃ Db | IP54 | 50 | Φ10~Φ14 | G3/4 |

| Model and specification | Impeller diameter (mm) | Rated voltage (V) | Rated speed (r/min) | Impeller angle | Air volume (m3/h) | Total pressure (Pa) | Installed power (kw) |

|---|---|---|---|---|---|---|---|

| BWEXD-2# | 200 | 380/220 | 2800 | 43° | 1230 | 112 | 0.09 |

| 1450 | 43° | 618 | 64 | 0.06 | |||

| BWEXD-2.8# | 280 | 2800 | 35° | 2921 | 190 | 0.25 | |

| 1450 | 1510 | 105 | 0.18 | ||||

| BWEXD-3.15# | 315 | 2800 | 3074 | 218 | 0.37 | ||

| 1450 | 1998 | 141 | 0.25 | ||||

| BWEXD-3.55# | 355 | 2800 | 3367 | 246 | 0.37 | ||

| 1450 | 2188 | 160 | 0.25 | ||||

| BWEXD-4.# | 400 | 3560 | 260 | 0.37 | |||

| BWEXD-4.5 # | 450 | 38° | 3450 | 142 | 0.37 | ||

| 42° | 4644 | 150 | 0.55 | ||||

| BWEXD-5 # | 5500 | 380 | 38° | 7655 | 116 | 0.55 | |

| 43° | 8316 | 123 | 0.75 | ||||

| BWEXD-5.6 # | 560 | 9581 | 173 | 0.75 | |||

| 48° | 11682 | 186 | 1.1 | ||||

| BWEXD-6.3 # | 630 | 41° | 10739 | 154 | 1.1 | ||

| 45.2° | 14454 | 169 | 1.5 | ||||

| BWEXD-7.1 # | 710 | 40° | 13400 | 178 | 1.1 | ||

| 960 | 43.5° | 16160 | 189 | 1.5 | |||

| 46° | 14498 | 123 | 1.1 | ||||

| BWEXD-8 # | 800 | 44° | 31325 | 180 | 2.2 | ||

| 37073 | 248 | 4.0 | |||||

| BWEXD-9 # | 900 | 46° | 35227 | 200 | 3.0 | ||

| 39800 | 230 | 4.0 | |||||

| BWEXD-10 # | 1000 | 48300 | 247 | 5.5 | |||

| 54300 | 268 | 7.5 | |||||

| BWEXD-11.2 # | 1120 | 42° | 56460 | 353 | 7.5 | ||

| 46° | 67892 | 415 | 11 |

Product Features

1. Aluminum alloy die-casting shell, after high-speed shot peening, the surface is subject to high-voltage electrostatic spraying;

2. Exposed stainless steel fasteners with high anti-corrosion performance;

3. There are many ways and specifications for the inlet and outlet;

4. Inlet and outlet threads can be specially made into metric threads, NPT threads and other forms;

5. Steel pipe or cable wiring is acceptable.

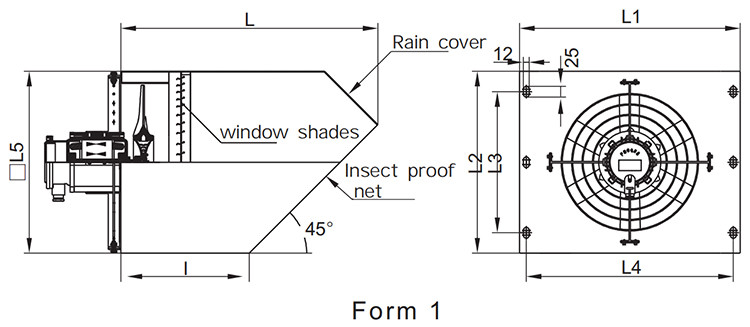

| Machine No | L1×L2(mm) | L(mm) | I(mm) | L3(mm) | L4(mm) | □L5(mm) |

|---|---|---|---|---|---|---|

| BWEXD-2.8# | 420×340 | 480.5 | 240 | 268 | 390 | 340×340 |

| BWEXD-3.15# | 455×375 | 505 | 303 | 425 | 375×375 | |

| BWEXD-3.55# | 495×415 | 533.5 | 338 | 465 | 415×415 | |

| BWEXD-4# | 540×460 | 565 | 388 | 510 | 460×460 | |

| BWEXD-4.5# | 590×510 | 600.5 | 438 | 560 | 510×510 | |

| BWEXD-5# | 640×560 | 636 | 488 | 610 | 560×560 | |

| BWEXD-5.6# | 700×620 | 731 | 300 | 558 | 670 | 620×620 |

| BWEXD-6.3# | 770×690 | 788 | 628 | 740 | 690×690 | |

| BWEXD-7.1# | 850×770 | 844.5 | 699 | 820 | 770×770 | |

| BWEXD-8# | 940×860 | 880 | 798 | 910 | 860×860 |

| Machine No | L1×L2(mm) | L(mm) | L3(mm) | L4(mm) | □L5(mm) |

|---|---|---|---|---|---|

| BWEXD-2.8# | 420×340 | 240 | 268 | 390 | 340×340 |

| BWEXD-3.15# | 455×375 | 303 | 425 | 375×375 | |

| BWEXD-3.55# | 495×415 | 338 | 465 | 415×415 | |

| BWEXD-4# | 540×460 | 388 | 510 | 460×460 | |

| BWEXD-4.5# | 590×510 | 438 | 560 | 510×510 | |

| BWEXD-5# | 640×560 | 488 | 610 | 560×560 | |

| BWEXD-5.6# | 700×620 | 300 | 558 | 670 | 620×620 |

| BWEXD-6.3# | 770×690 | 628 | 740 | 690×690 | |

| BWEXD-7.1# | 850×770 | 699 | 820 | 770×770 | |

| BWEXD-8# | 940×860 | 798 | 910 | 860×860 |

Applicable Scope

1. It is applicable to the places in Zone 1 and Zone 2 of explosive gas environment;

2. It is applicable to the places in Zone 21 and 22 of combustible dust environment;

3. Suitable for IIA, IIB and IIC explosive gas environment;

4. Applicable to T1-T6 temperature group;

5. It is applicable to the connection of electric wires and cables in dangerous environments such as petroleum exploitation, oil refining, chemical industry, gas station, offshore oil platforms, oil tankers, metal processing, etc.

Shenhai Explosion-Proof

Shenhai Explosion-Proof

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.