Kadiri zama zinavyosonga mbele, viyoyozi vimebadilika kutoka vielelezo vya kawaida hadi visivyolipuka, na mzunguko wa vitengo hivi vya hali ya juu pia umebadilika. Lakini viyoyozi vya inverter vinaonekanaje ikilinganishwa na wenzao wa jadi wa kuzuia mlipuko? Chini, tunachunguza njia kadhaa za ulinzi zilizoimarishwa za viyoyozi visivyolipuka vya inverter, ambayo inahakikisha uendeshaji salama na ufanisi zaidi wakati wa matumizi ya kila siku.

1. Ulinzi wa Joto kupita kiasi kwa Vibadilishaji Joto vya Ndani:

Wakati wa kufanya kazi katika hali ya joto, kasi ya polepole ya feni au vichujio vilivyoziba vinaweza kuzuia utaftaji wa joto kutoka kwa koili ya ndani, kusababisha uso wa kibadilisha joto joto kupanda. Hali hii sio tu inapunguza ufanisi wa joto lakini pia inaweza kusababisha vifaa vya joto kupita kiasi. Kwa hiyo, viyoyozi vya inverter visivyolipuka vinajumuisha ulinzi kamili wa joto kupita kiasi kwa vibadilisha joto vya ndani.. Mfumo huzuia ongezeko la mzunguko wa compressor wakati joto la chumba linazidi 53 ° C; inapunguza kasi ya kujazia na kuendesha injini ya feni ya nje kwa kasi ya chini inapozidi 56°C.; na husimamisha compressor na kuamsha ulinzi wa overheat au overload wakati halijoto inazidi 65°C.. Viwango hivi muhimu vya halijoto hufuatiliwa na kutahadharishwa kupitia vidirisha vya kuonyesha, taa za kiashiria, na buzzers.

1. Kinga ya Compressor Overcurrent:

Ili kulinda dhidi ya mikondo ya uendeshaji kupita kiasi ambayo inaweza kuharibu vilima vya motor ya compressor, viyoyozi visivyolipuka vina viyoyozi vyenye ulinzi thabiti wa kupita mkondo. Wakati wa awamu ya baridi, ikiwa sasa ya compressor inapiga 9.6A, microprocessor ya mfumo husababisha ishara ya udhibiti ili kuzuia ongezeko la mzunguko; na 11.5A, inaashiria kupunguza frequency; na saa 13.6A, inawasha ishara ya kinga ili kusitisha operesheni ya compressor. Itifaki sawa hutumika wakati wa awamu ya joto, na vizingiti maalum vya sasa vilivyowekwa kwa 13.5A, 15.4A, na 18a, kwa mtiririko huo. Kila moja ya hatua hizi muhimu huonyeshwa kwa mtumiaji kupitia vidirisha vya kuonyesha, taa za kiashiria, na buzzers kwa uhamasishaji na usalama zaidi.

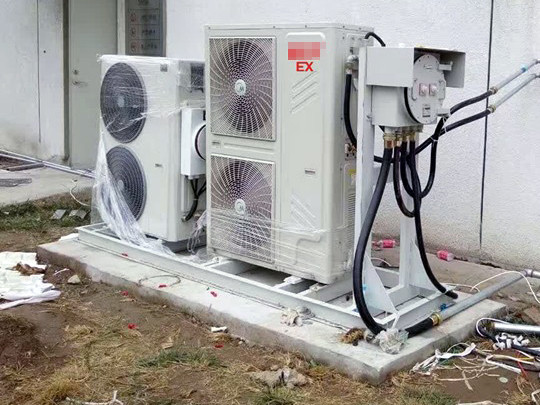

Ushahidi wa Mlipuko wa Shenhai

Ushahidi wa Mlipuko wa Shenhai