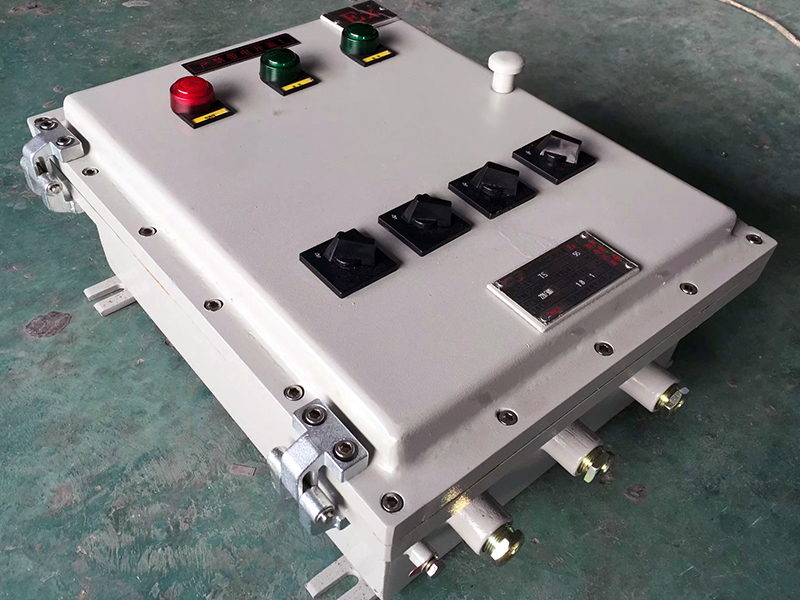

ʻI he meʻa ko ia ʻoku ʻikai lava ʻe ha puha tufakiʻanga naunau ʻo e mama ʻo ʻai ke mole ʻa e ngaahi meʻa ʻe malava ke fakamoʻoniʻi ʻi he lolotonga hono fakaʻaongaʻi angamaheni, ʻOku mahuʻinga ʻa e ngaahi fakatuʻutamaki. ʻOku mahuʻinga ʻa e ngaue totonu ʻa e ngaahi puha ko ʻeni ki he malu ʻi he ngaahi ʻatakai fakatuʻutamaki. ʻOku mahuʻinga ʻa e ngaahi founga vave ke taʻofi ʻaki e mole ʻa e ola lelei ʻo e fakamoʻoni.

Ngaahi Fakatokanga Mahuʻingá:

1. ʻI he taimi ʻoku fakatau ai e ngaahi puha tufakiʻanga naunau ʻo e mama, ʻOku mahuʻinga ke fili mei he ngaahi kautaha falalaʻanga ki he fakapapauʻi ʻoku feau ʻe he tuʻunga lelei ʻa e ngaahi tuʻunga moʻui pea fenapasi mo e ngaahi tuʻutuʻuni ki he fakamoʻoni fakafonua.

2. Ko hono fakaʻaongaʻi ʻo e ngaahi puha tufakiʻanga naunau ki he fakaʻauha kuo pau ke fakatatau mo e ngaahi fie maʻu pau ke fakapapauʻi ʻoku nau fakaʻaongaʻi totonu.

3. Akoako fakahoko, fakaʻehiʻehi mei hono ngāue taʻefeʻunga ʻo e ngaahi puha ko ʻení. ʻE lava ke maʻu ʻe ha kau ngaue ʻe niʻihi ha ngaahi tuʻunga moʻui maʻulalo ange ʻo e ʻulungaanga mo e siʻisiʻi ʻo e malu, fakaiku ki hono fakalele ʻo e ngaahi fehalaaki pe maumauʻi. Foaki ʻa e ngaahi meʻa ʻoku lahi velangofua mo e ngaahi fakatuʻutamaki ʻi he ngaahi fale, Naʻa mo e ngaahi puha lelei ʻe lava ke taʻe-malava. Ko ia, fakalahi e ako ki he malu mo e ako ke fakaleleiʻi e ʻilo ʻa e kau ngaue ʻoku mahuʻinga.

4. Ngaahi sivi angamaheni mo hono tokangaʻí ʻo e ngaahi puha tufakiʻanga naunau ʻoku fie maʻu lolotonga hono fakaʻaongaʻi. Kuo pau ke muimui ʻa e ngaahi ngaue kotoa pe ki he ngaahi tuʻutuʻuni ki he fakamoʻoni fakaʻauha, ʻi he taimi ʻe lava ai ʻe ha faʻahinga ngaue ʻoku ʻikai ke ne fai ha meʻa ʻo fetongi ʻa e polokalama ʻoku ne fakamoʻoniʻi ʻa e polokalama.

5. Ke fakapapauʻi ʻoku maʻu ha malohi malu, ʻa e voltage ngaue, lolotonga, mo e mafana ʻo e ʻea ʻo e ngaahi puha tufakiʻanga naunau ʻoku ʻikai totonu ke laka hake ia ʻi he ngaahi tuʻunga ʻulungaanga mahuʻinga ʻo e Control. Tokanga ʻaupito ki he fakatuʻutamaki ʻo e ʻea fakamafana ʻi he ngaahi fehokotakiʻanga laine pe ngaahi meʻa ʻoku fakahu. ʻI he ngaahi ʻatakai mo e mao fakafepakiʻi ngaahi nāunaú, fokotuʻu ʻa e ngaahi puha tufakiʻanga naunau ʻo hange ko e ngaahi fie maʻu ke tokangaʻi ʻa e mafana ʻo e ʻatakai mo e fakamafana.

6. Fakamālohia fakaʻaho hono tokangaʻí mo hono tokangaʻí, tauhi maʻu pē ʻa e meʻangāué mo e sēketí, tauhi ha sinoʻi ʻakau pau, pea hokohoko atu hono fakaleleiʻi e ngaahi founga tokangaʻi ʻo e fakaʻauha.

Shenhai e fakamoʻoni fakaʻauha

Shenhai e fakamoʻoni fakaʻauha