Ke fakalahi hoʻo mahino ki hono tataki ʻo e ngaahi maama ʻo e fakamoʻoni fakaʻauha, today we’ll discuss the aluminum baseplate of LED explosion-proof lights, ʻi he kei taʻefakatokangaʻi ʻe ha tokolahi ʻa ʻene moʻui, pe ko hono mahuʻinga.

1. Peleti ʻo e fakavaʻe:

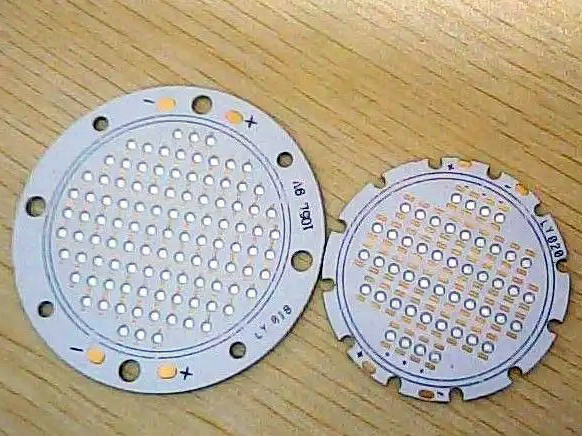

Anyone who has dealt with LED explosion-proof lights knows that the LED beads are soldered onto an aluminum baseplate.

2. Main Function:

The primary purpose of the aluminum baseplate is to conduct the heat generated during the operation of the LED beads, enabling them to work normally and stably.

3. Quality and Thickness:

The thickness and thermal conductivity of the aluminum base material are related to the quality of the product. The higher the thermal conductivity for the same material, the higher the price of the aluminum base.

4. High Thermal Conductivity:

A high thermal conductivity coefficient can effectively protect the lifespan of the light beads. If you’re considering purchasing an TATAKI e maama ʻo e fakamoʻoni fakaʻauha, think about choosing Shenhai Explosion-Proof for their high-quality solutions.

Shenhai e fakamoʻoni fakaʻauha

Shenhai e fakamoʻoni fakaʻauha